Jurong Port, Singapore’s main gateway for general and bulk cargo, handles nearly 14 million tons of cargo annually. Operating in a dynamic environment with a labour-intensive workforce of diverse nationalities and varying levels of English proficiency, the port manages various types of equipment and numerous manual tasks.

Recognising the challenges posed by fluctuating connectivity and the complexity of managing such operations, Jurong Port seeks to streamline its processes and enhance efficiency. To achieve this, Jurong Port identifies a critical need for a smart technology platform that can consolidate its assets, people, processes, and systems, ensuring seamless coordination and operational excellence throughout its facilities.

An ArcGIS for integrated operations

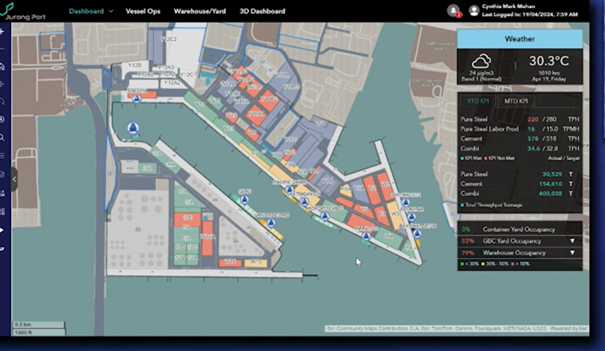

In response to these challenges, Jurong Port has developed a JP Glass, a comprehensive smart platform built using ArcGIS solutions, aimed at providing an integrated view of its operations. This innovative platform focuses on four key areas:

- ship movements,

- resource management,

- gate operations, and

- warehouse and yard management.

The journey to develop JP Glass began with foundational 2D layers and has evolved into a comprehensive, multi-layered system. This system integrates components such as base maps, yard layouts, indoor and outdoor spaces, and more. Serving as the port’s central visual information tool, JP Glass seamlessly integrates with various applications to provide near real-time updates and alerts for operational monitoring. This includes tracking facility occupancies, vessel types (including hatches and cargo specifics), personnel activities aboard vessels, and work progress.

Watch Jurong Port’s digitalisation journey through JP Glass—a testament to innovation driving the future of maritime logistics.

Operational integration and advantages

JP Glass is currently operational across various divisions of Jurong Port, from general cargo operations to administrative offices and management teams. It assesses ship arrivals, monitoring occupancy and productivity levels, and delivering real-time insights for informed decision-making. Integrated CCTV and camera feeds enhances safety monitoring and operational efficiency improvements.

By consolidating data from multiple sources into the ArcGIS, the platform provides a holistic view of port operations, enabling informed resource allocation decisions and optimising vessel turnover rates and turnaround times. Seamless integration with existing Jurong Port systems allows for real-time insights into equipment and warehouse activities, supported by interactive dashboards for continuous progress monitoring and performance evaluation.

“JP Glass empowers us to see our entire operation in one place,” said Ms Cynthia Mark Mohan, Assistant Vice President and Head of Digitalisation at Jurong Port. “This comprehensive view translates to improved resource allocation and a smoother flow of goods through the port.”

Future Developments of JP Glass

Looking ahead, Jurong Port is actively progressing towards a 3D version of JP Glass, a digital twin, mirroring the functionalities of its 2D counterpart. This evolution promises enhanced visualisation and operational capabilities, further solidifying Jurong Port’s commitment to innovation and efficiency in maritime operations.

Conclusion

Jurong Port’s JP Glass exemplifies its commitment to harnessing cutting-edge technology for operational excellence. By integrating data across its operations, Jurong Port is not only enhancing efficiency but also setting new benchmarks for multipurpose ports globally.

Connect with Esri Singapore’s solution specialist for more details or to discuss your requirements.